Onay Socks

The foundation of Onay Socks was laid in 1980 in a modest workshop in Istanbul by Kerim Gürbüz. What began in this workshop gradually transformed into the goal of becoming one of Turkey's leading sock manufacturers. This journey, which started with sock toe stitching machines in the early years, took a significant leap in 1995 with the acquisition of 'Lonati' brand computerized sock knitting machines, leading to the establishment of Onay Socks in 2003. Onay Socks has secured a strong position in the industry with its innovative approach and commitment to high quality.

Read More

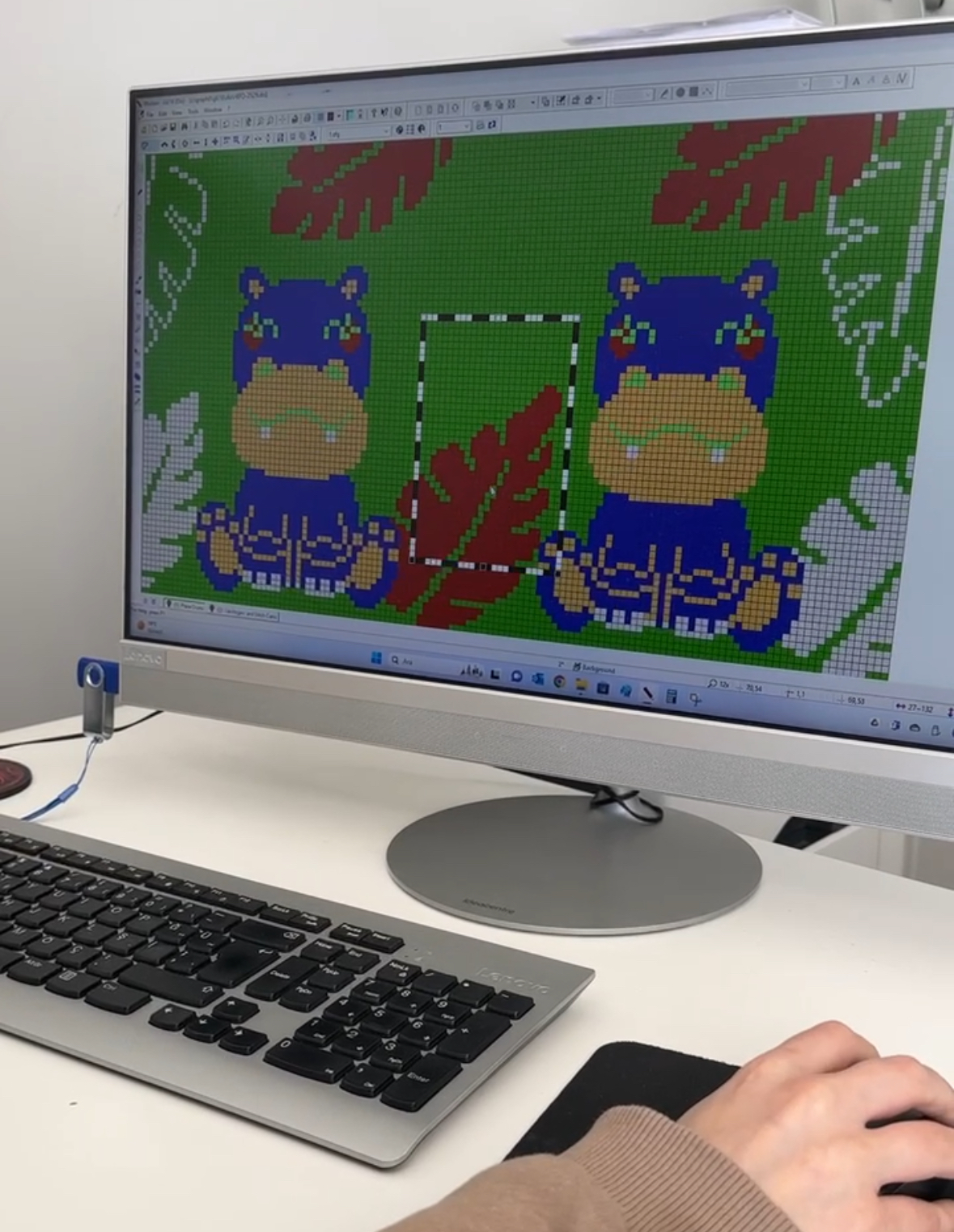

Pattern Design

Our production process begins with the meticulous development of creative pattern designs. Our expert design team considers not only aesthetic appeal but also the functional needs of the socks, creating unique and stylish patterns. We carefully listen to our customers' requests, ensuring that the designs we create meet their expectations in every detail. This stage is crucial in defining the character, quality, and style of our socks.

Yarn Selection and Sample Production

Selecting the right yarn is an essential step in producing high-quality socks. During this stage of the production process, we carefully choose yarns that offer maximum durability, softness, and comfort. The selected yarns and patterns are then used to create samples, allowing our customers to preview the final product in terms of design and functionality. This ensures customer satisfaction before full-scale production begins, allowing for any necessary revisions.

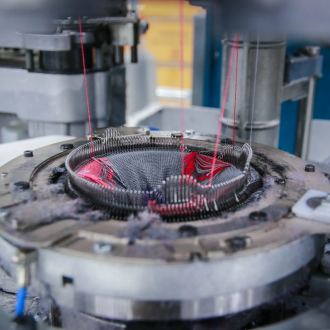

Production and Quality Control

Once the samples are approved, we move on to full-scale production. At this stage, each sock is meticulously produced using our state-of-the-art machinery. Throughout the production process, our quality control teams conduct detailed inspections to ensure that each product meets the established standards. Continuous quality checks during production guarantee that we consistently deliver socks of the highest quality to our customers. We work with precision, balancing production speed and efficiency with the attention to detail required to achieve perfection.

Washing

After production, our socks undergo special washing procedures to enhance their quality and comfort. During this stage, the softness and elasticity of the socks are maximized, while the vibrancy of the colors is preserved. We also offer additional processes such as antibacterial washing, based on our customers' needs, ensuring that the socks are not only hygienic but also durable.

Ironing and Packaging

Following the washing process, our socks are ironed using state-of-the-art automatic steam press machines to achieve a flawless appearance. This ironing process ensures that the socks are presented in a neat and aesthetically pleasing manner. After ironing, each sock undergoes a final quality control inspection before being meticulously packaged. The products are then packed according to the customer’s specified box sizes.

Shipping

Once prepared for shipment, the boxes are palletized to ensure they are suitable for transportation. Each box is carefully stretch-wrapped and strapped to minimize the risk of damage during logistics processes. This preparation ensures the safety of the products during transit. The pallets are then arranged for air, sea, or land transportation, and dispatched to our customers around the world with the utmost care. This meticulous process ensures that the quality and integrity of our products are maintained until they reach their destination.

Our Company Values

Learning Attitude

The willingness to learn from everything around us. A positive, open-minded attitude that allows you to grow more.

Team Working

The ability to work as part of a team. Being able to share expertise and optimize interdisciplinary team work.

Customer Satisfaction

Never lose sight of the most important goal: customer satisfaction. This is the main motivation of our work.

Excellence Inspired

The drive to achieving excellent results can only be powered by the highest quality standards. Excellence as a method of ongoing development.

Target Focusing

Every action becomes more effective if it has a clear, determined objective. Focusing on resources and activities generates the best results.